Valve repairing includes stop valves and non-return valves and control valves

The repairing specifications include standard and extra activities:

Standard repair consist in the following steps:

- Actuator disassembly

- Bonnet and gland disassembly

- Cleaning and examination of the state of the internal parts and the stem

- Check of actuator efficiency

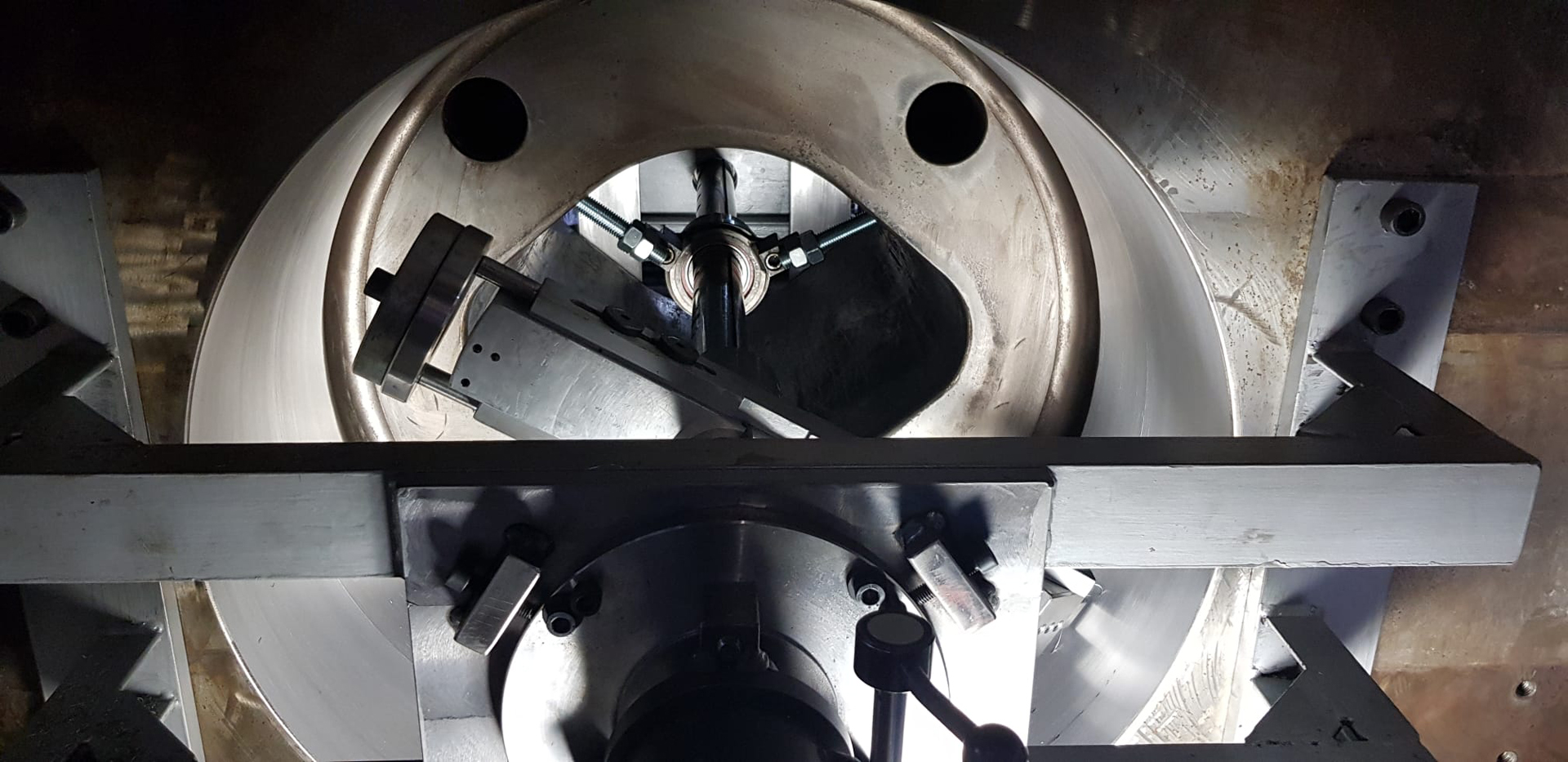

- Lapping of the seats

- Grinding of the plug or replacing it with a new part

- Polishing of the stem or its replacement with a new part

- Various parts and re-assembling

- Functional testing

- Seal testing

- Repainting with paint suitable for high temperature

- Attack recovery

During the repairing, the following extra activities may be necessary, which must in any case be authorized by the Customer:

EXTRA WORK

- Replacement of seats

- Welding coatings on the seats and consequent machining (not to be carried out on site)

- Welding coatings on the plug and consequent machining

- Reconstruction of spare parts with reverse engineering

- Body/bonnet seal repairing

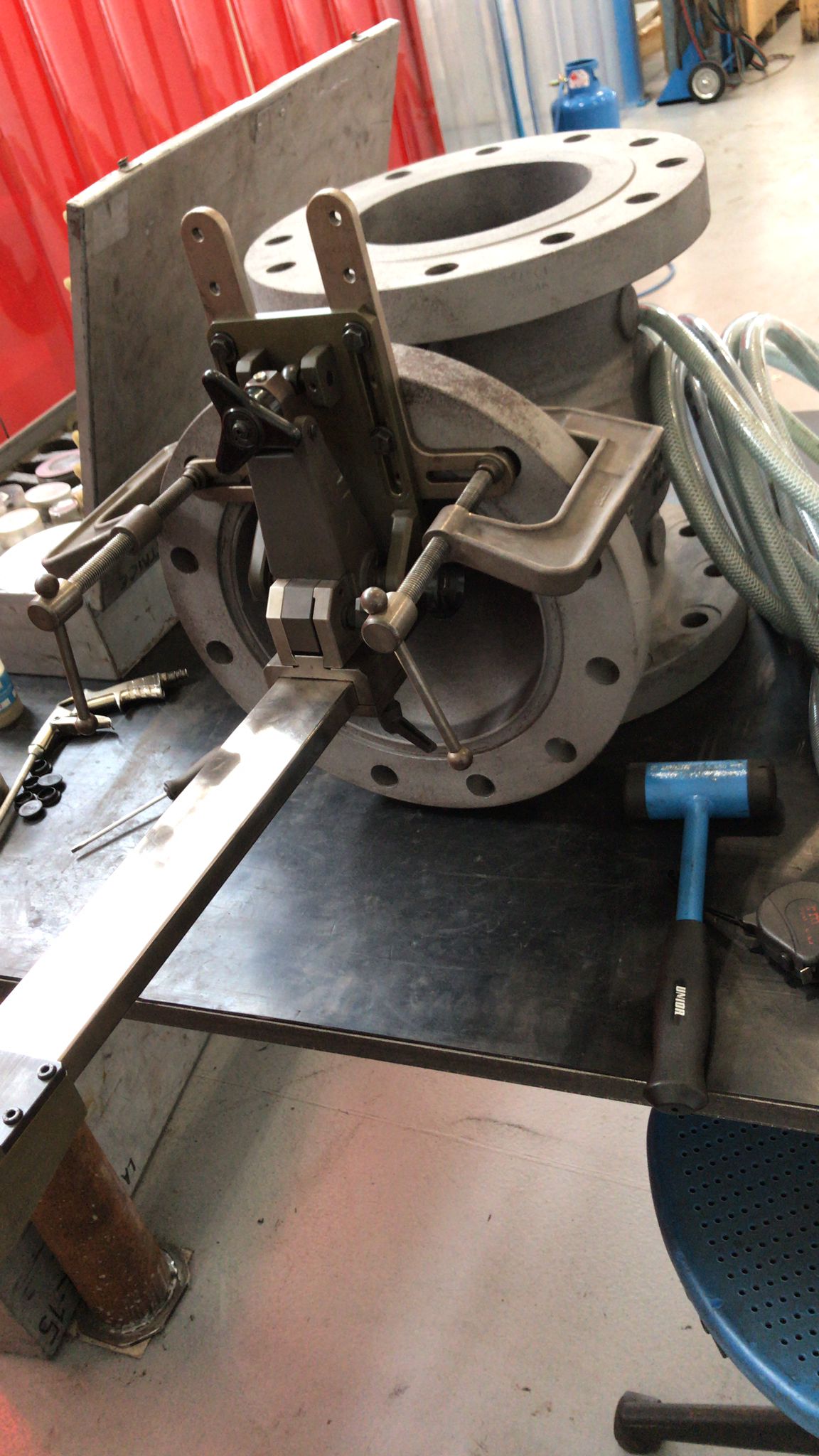

List of equipment:

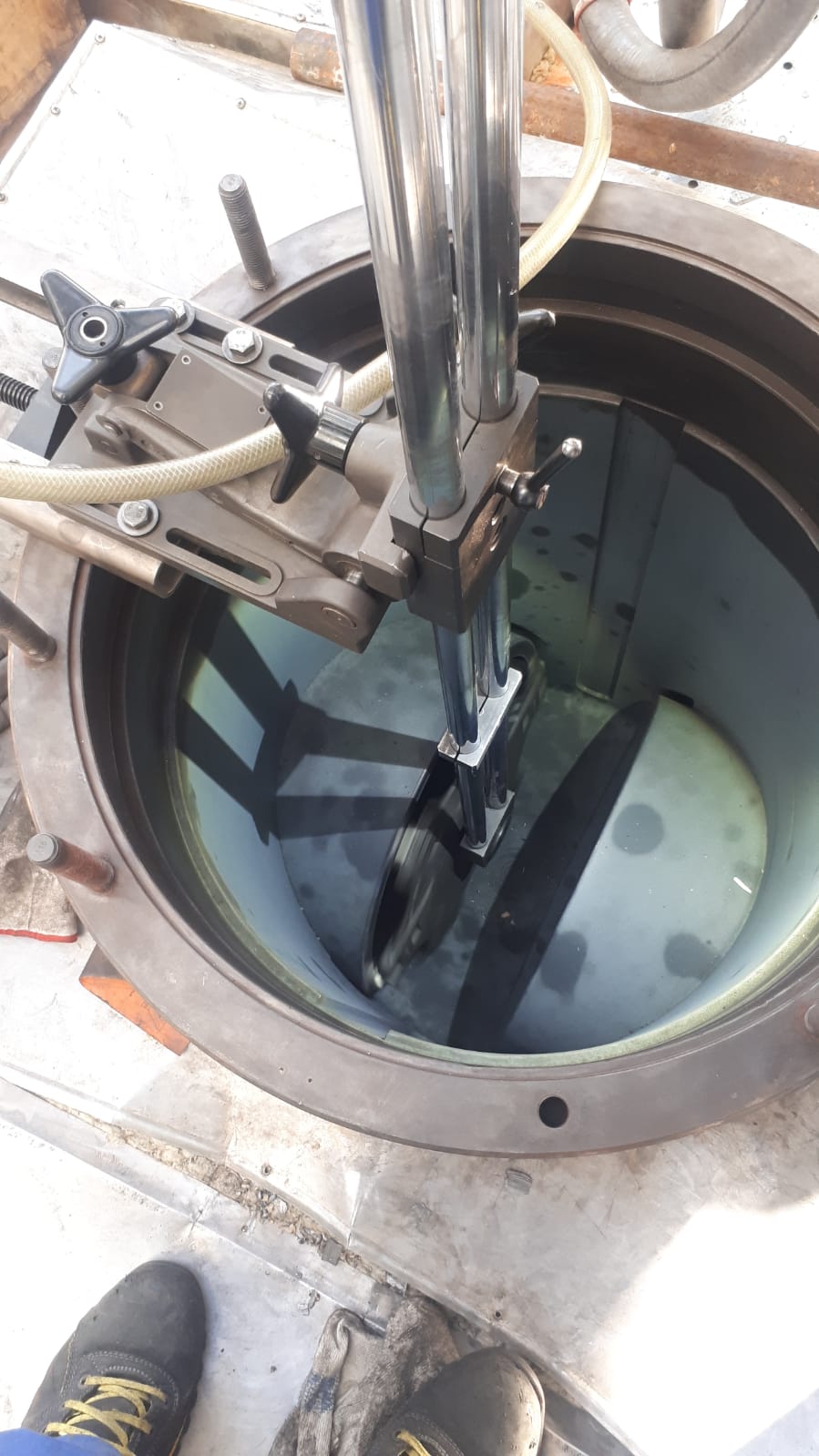

LAPPING MACHINE UP TO 12"

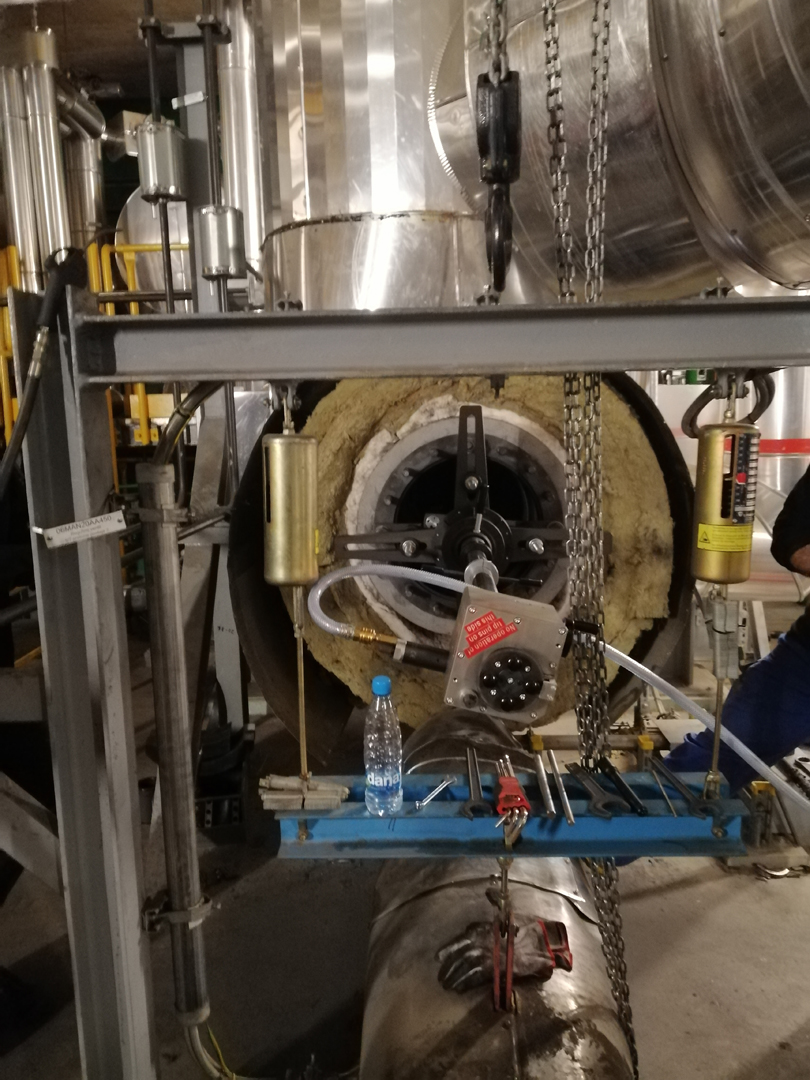

LAPPING MACHINE FROM 8" TO 32"

GRINDING machine UP TO 24

Reverse engineering

The construction of spare parts is a consolidated practice in cases of urgency and immediate unavailability by the manufacturer when plant downtime emergencies do not allow a scheduled supply