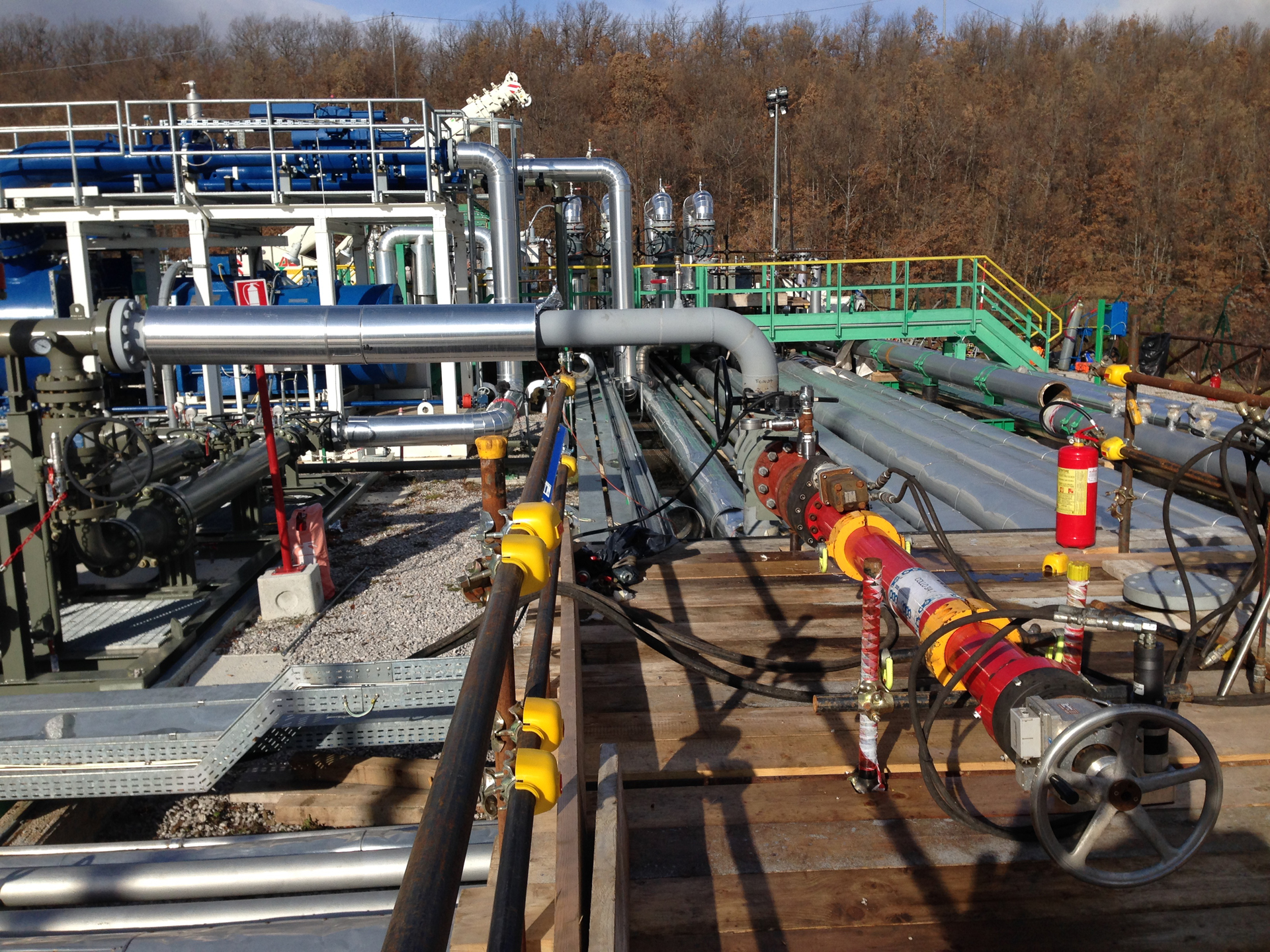

A branch connection is prepared on a main pipe before drilling is performed.

Depending on the circumstances, the branch connection (which can have the same diameter as the actual main pipe) can be welded onto the piping to be drilled using a round bolstering plate 1.75 times the diameter of the hot tap. Alternatively, it can consist in an actual split tee that encircles the entire diameter of the pipe.

When the flange from which the branch connection is ready, the root valve is installed and drilling is performed.

Applications

Creation of branch connections under pressure on water, gas and hydrocarbon piping, 30° and 45° angled hot tap, hot tap in tanks.

Capabilities

Drilling under pressure up to 24" at pressures of up to 100 bar on stainless and carbon steel.

TTA's technology and skill make it possible to offer sizes larger than these upon specific request and on reasonable notice.

Procedures

The hot tapping phases consist of:

- Installing the branch connection,

- Mounting the root valve,

- Applying the drilling machine onto the open root valve,

- Drilling the header,

- Recovering the part removed by the drill,

- Closing the root valve,

- Removing the drilling machine.