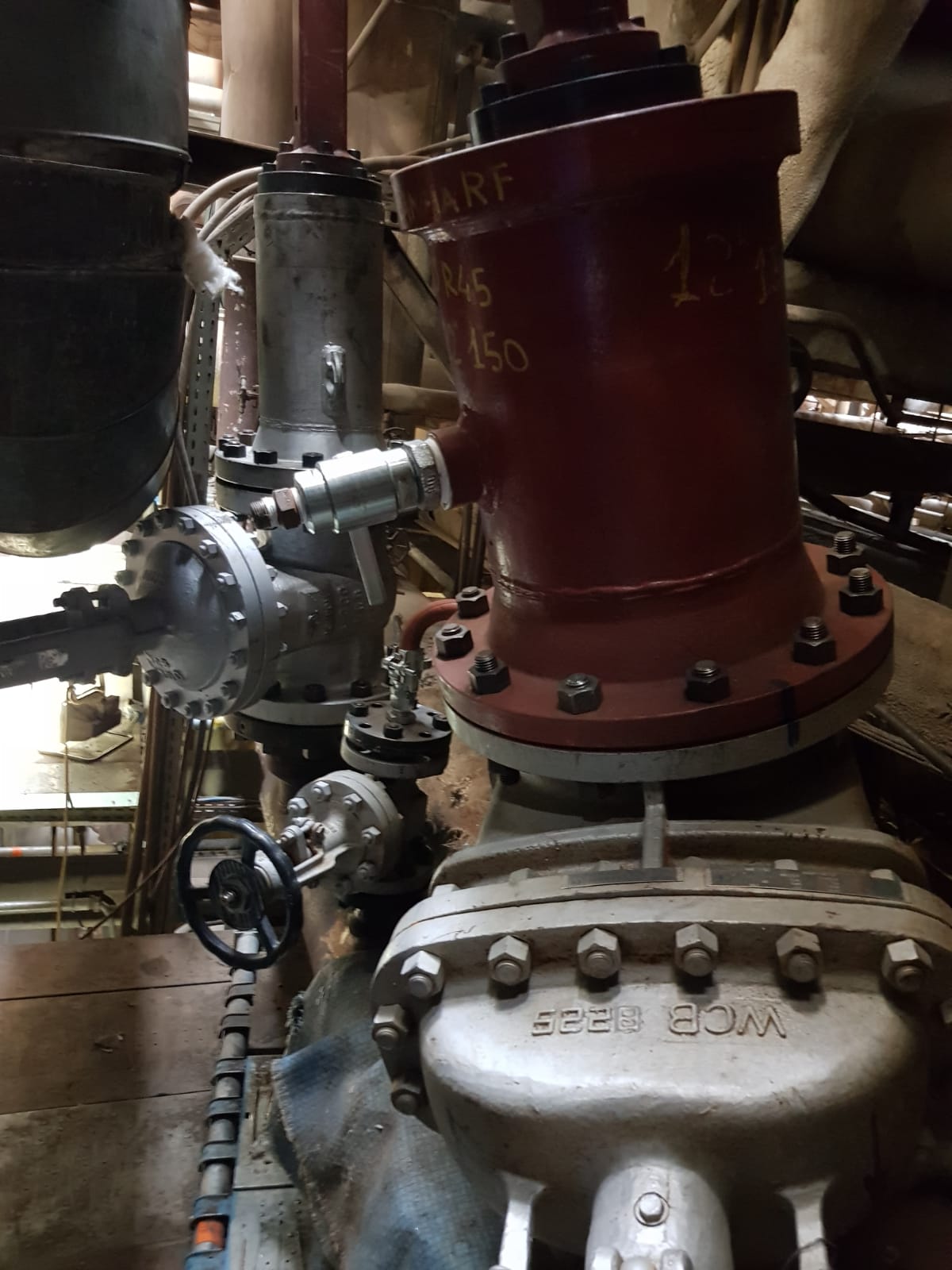

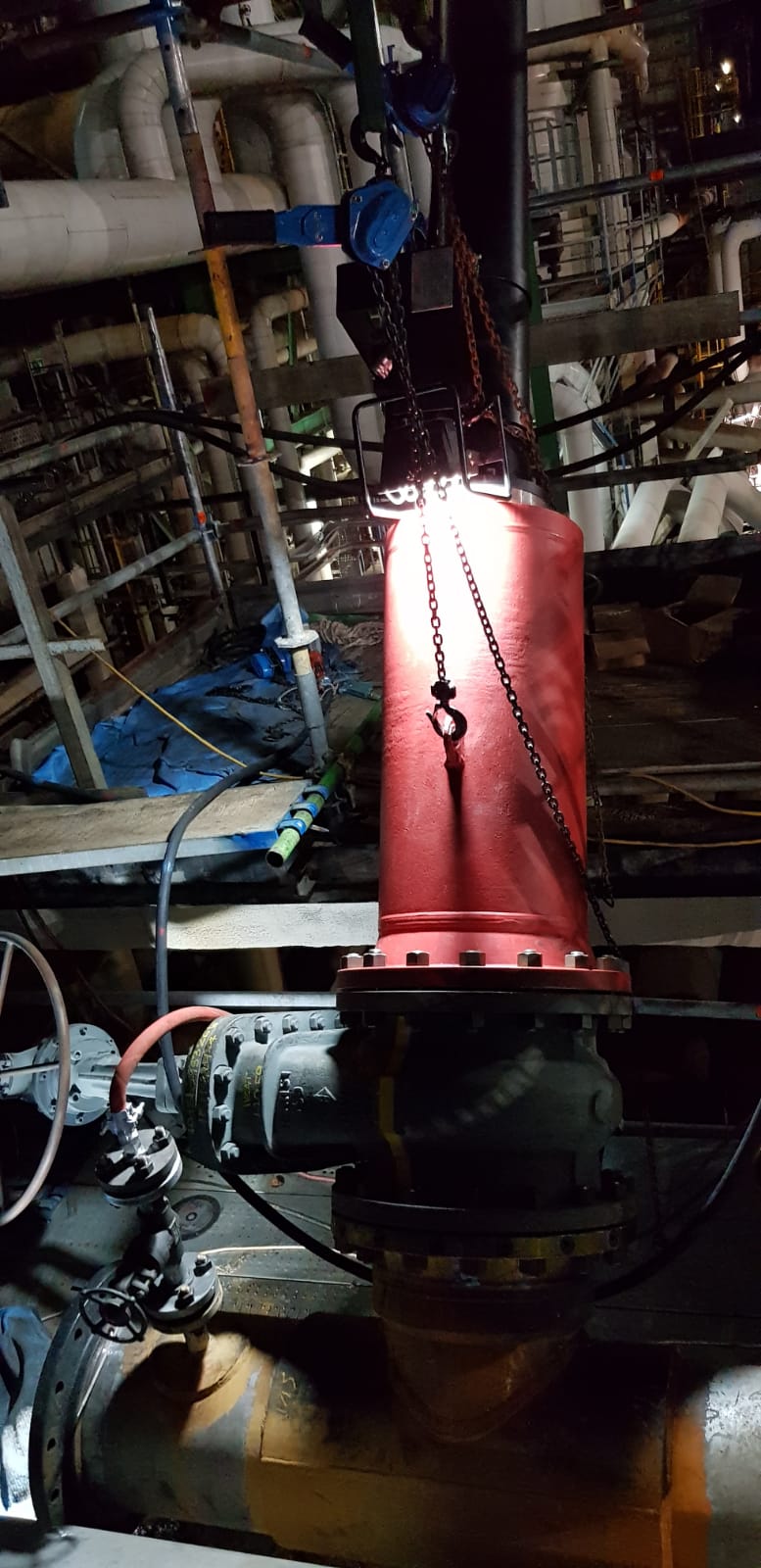

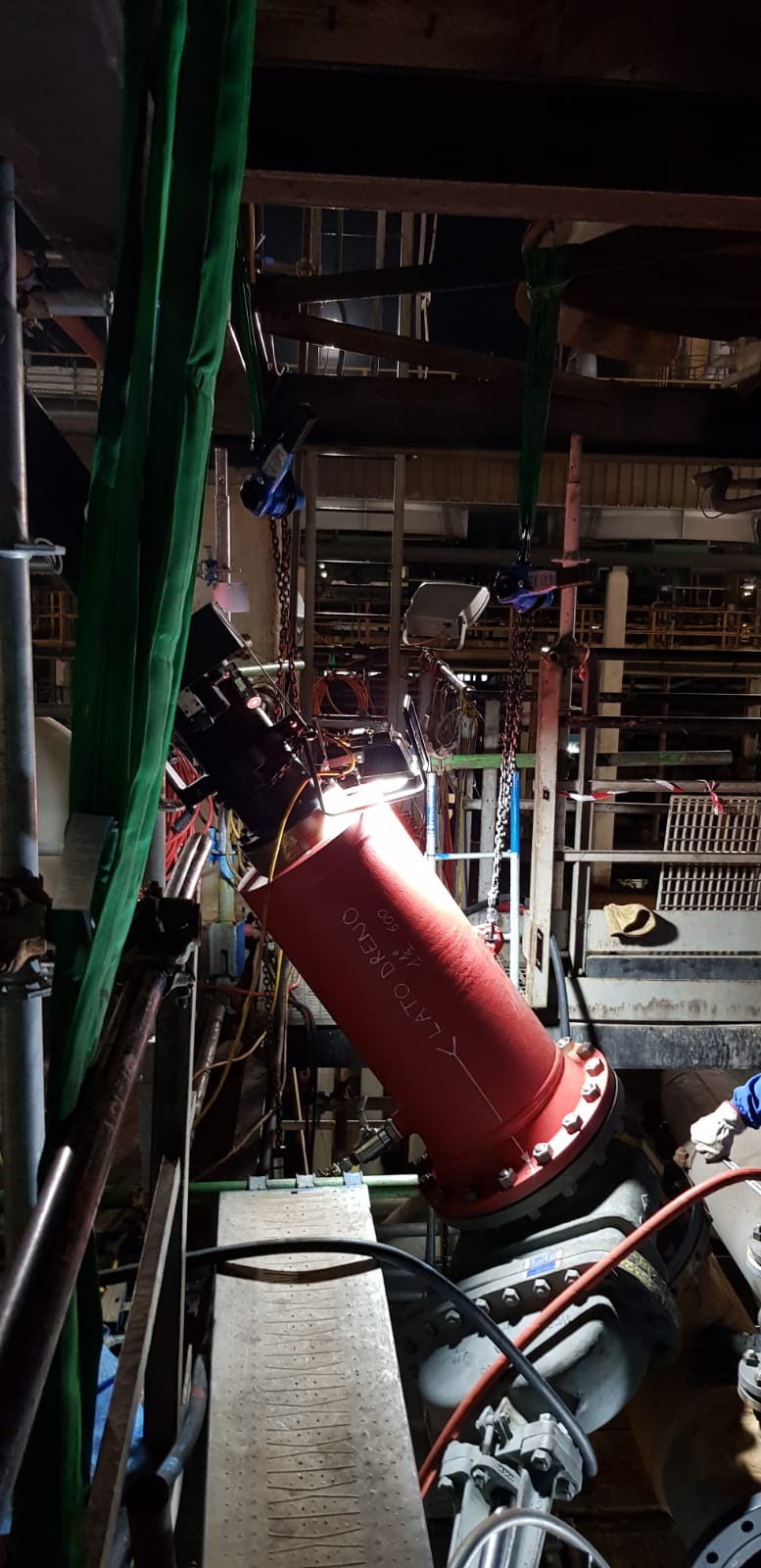

The line stop activity allows to temporarily interrupt the flow inside a pipe to allow the repair of a damaged section or the insertion of valves or other plant elements.

Line stopping is performed by inserting a plug in the line.

If a perfect seal is required further down the line, after the flow stop, the plug will be double and in this case drainage will be required between the two plugs.

Applications

Line stopping using a single or a double plug allows work to be performed further down the line.

Double line stopping allows damaged piping sections to be repaired.

Alternatively, a temporary bypass can be made by connecting special machines together.

Temporary bypasses to add valves or other equipment.

Permanent bypasses using hot tapping or by means of three-way split tees.

Capabilities

Up to 24" at pressures of up to 100 bar on stainless and carbon steel.

TTA's technology and skill make it possible to offer sizes larger than these upon specific request and on reasonable notice.

Procedures

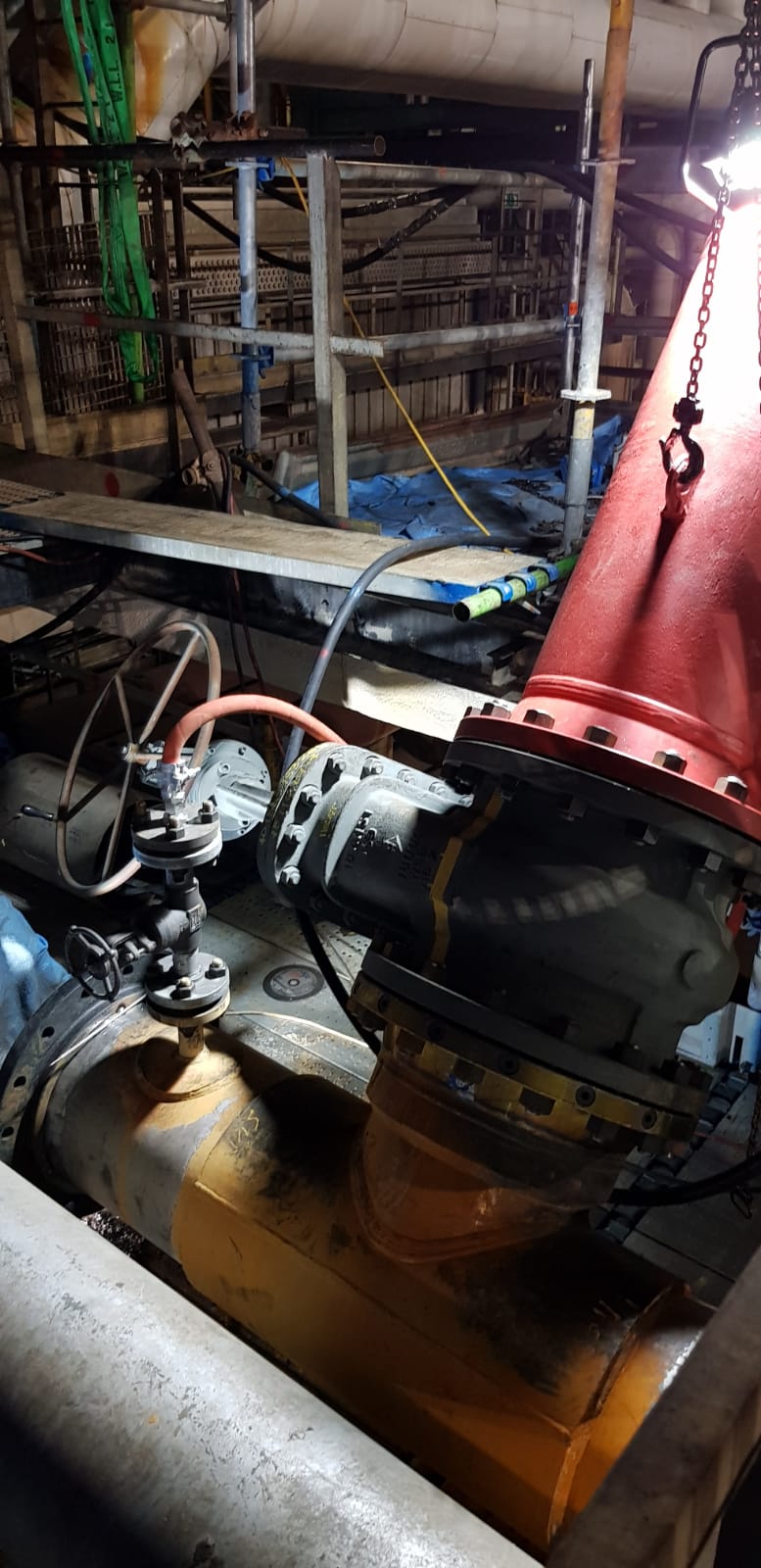

- Under pressure drilling of a hot tap with a diameter equal to the one of the header,

- Inserting of flow stop plug (single or double),

- Waiting for the operations for which the line stopping was required to be completed,

- Removal of the plug,

- Application of the cap on the split tee flange,

- Mounting the blind flange.